With the progress in mobile phone’s technology, nowadays slimmer and thinner devices are arriving the market. The screen along with the body of the device are getting so thin that the screen material is to be given special importance. OLED screens will fail to withstand physical pressure or hazard if the thickness reduces beyond its threshold limit. Hence the South Korea’s Electronics and Telecommunications Research Institute are working on using Graphene in the OLED screens.

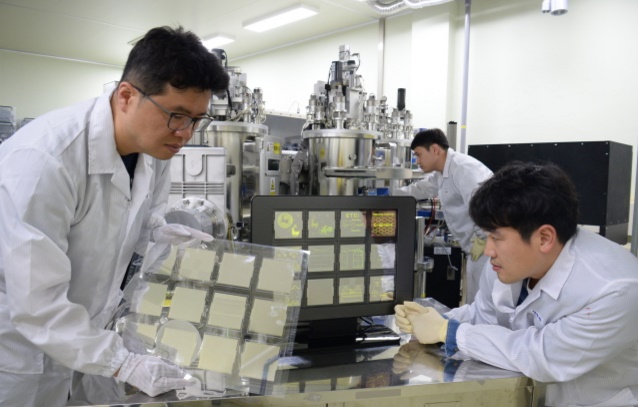

Eminent scientists from the research institute announced that they have been able to develop transparent electrodes for organic light-emitting diode displays out of graphene. The goal has been accomplished in collaboration with Hanwha Techwin. Now technically speaking, Graphene is a material which is considered to be the thinnest and most flexible material. It is also the fastest in transferring heat and electricity among all the existing materials that are currently used. The use of Graphene is increasing as the demand for thin devices and thinner displays is escalating.

ETRI and Hanwha said that their joint venture has been able to bore fruits of success. Indium Tin Oxide (ITO) which has been widely used make transparent electrodes in OLED panels will now be replaced by graphene. Unlike ITO, this material is super flexible and hence doesn’t succumb to chipping. The research team used graphene on the largest OLED panel on earth, which is 370 millimeters in length and 470 mm in width. The thickness of the graphene electrode was less than 5 nanometers. Researchers also invented a process for patterning graphene-based transparent electrodes with specific numbers and shapes on the OLED substrates, which could be applied for developing flexible smart devices in the future.

“It is meaningful that we are the first to apply graphene to OLED panels,” Cho Nam-sung, head of ETRI research team,

said. “The technology would help elevate Korea’s OLED panel technology by widening the technology gap with Chinese rivals.”

“Companies are making similar efforts to develop fordable display panels by minimizing the use of ITO electrodes by applying other materials such as plastics,” said a spokesman at LG Display. “If commercialized soon, the graphene electrode technology would help the industry achieve fordable panels significantly.”

Leave a Reply